Delta´s Modular Data Centers

Delta´s Modular Data Centers

Smart Solutions from Consultation to Construction

As data processing and network demands surge – with AI, 5G, IoT, and cloud services driving unprecedented data volumes – traditional data center builds simply can’t keep pace. Delta’s process begins with a comprehensive pre-sales consultation. Our design experts work closely with you to analyze site-specific requirements and network challenges, crafting customized, scalable layouts that not only meet today’s needs but are flexible enough for future network expansions. This consultative approach ensures every solution is engineered to your exact requirements while addressing cost pressures and competitive challenges highlighted in our white paper.

Precision Engineering in Croatia

At the high-tech factory in Croatia, smart engineering takes center stage. Premium-grade steel is meticulously inspected for durability and cut to precise specifications using advanced CNC laser technology. Through machine bending and precision welding – secured with industrial-grade coatings – each module is built to be both robust and long-lasting. This controlled, factory-based construction minimizes on-site disruptions and guarantees consistency, reflecting the advantages of a prefabricated approach that our white paper identifies as key to reducing overall capital costs and enabling a “pay-as-you-grow” strategy.

Integrated Testing for Peak Performance

Once constructed, the modules move to a dedicated assembly facility where our technicians integrate all essential systems: Uninterruptible Power Supply (UPS) & Power Distribution, Precision Cooling Systems, Server Racks & IT Infrastructure, Security & Access Control, and Monitoring & Management (DCIM & Environmental Sensors). Each component is subject to rigorous Factory Acceptance Testing, ensuring structural integrity and system reliability before shipment. This pre-testing phase not only reduces the installation timeline but also minimizes the risk of on-site delays – an essential factor when deploying networks in fast-paced telecom environments.

Seamless Delivery and Rapid Deployment

After passing all quality checks, the modular units are carefully secured for transport. At the destination, our team orchestrates a seamless reassembly process that delivers a fully operational data center solution up to a year faster than conventional builds. By leveraging standardized, pre-integrated components, Delta’s approach minimizes on-site labor and complexity, allowing network operators to rapidly expand capacity and respond to traffic surges. As our white paper explains, this rapid deployment is a competitive advantage that supports dynamic market demands while keeping capital expenditures in check.

Efficiency Delivered, Complexity Simplified

Delta Electronics’ modular data centers exemplify the smart approach to modern infrastructure. Our solutions offer:

- Cost Efficiency: By streamlining construction in a controlled environment, overall costs are reduced and risks associated with traditional builds are mitigated.

- Sustainability: Factory-controlled production minimizes waste and energy consumption, with systems designed for optimal energy efficiency – supporting telecom operators’ sustainability and CO₂ reduction targets.

- Agility and Scalability: Modular design allows operators to add capacity incrementally, aligning infrastructure investments with actual network demand.

- Future-Proofing: Tailored for evolving telecom requirements, our MDCs support advanced services from 5G to edge computing, ensuring your infrastructure adapts as technology evolves.

With a focus on quality, rapid deployment, and energy efficiency, Delta’s modular data centers combine the best of precision Croatian engineering with a smart, scalable approach to meet the challenges of today’s fast-evolving telecom landscape.

Talk to us today to learn how our modular solutions can power your digital future and help you stay ahead in a rapidly evolving market.

Telecoms site backup batteries are a legal requirement in most developed countries – operators need to prove they can keep critical services running during a power outage.

However, compliance comes at a considerable cost. Because the grid is reasonably stable in Europe, you’re typically replacing lead-acid batteries every 7-8 years that are seldom (if ever) used.

So far, so frustrating. But Delta is helping a major European telecoms provider disrupt the status quo with li-ion (lithium-ion) batteries and smart power. And buying grid power so efficiently, its backup batteries come effectively at no cost.

How Smart Power saves you money

Before we zoom in on our case study, here’s a high-level reminder of the various ways Smart Power can save you money:

- Peak Shaving uses preset or on-demand battery energy during peak demand from the grid to avoid charges related to power consumption above a certain threshold.

- Tariff Control is preset or on-demand use of battery energy stored during high-cost hours and recharged during low-cost hours (or via renewables like solar, if available).

- Demand response is on-demand battery energy use to offload a certain amount of energy in a set time period.

Now, let’s see it in action.

Backup batteries: your site’s sleeping giants

Smart power innovations are already invaluable to this particular telecom client, which manages a fleet of 700 sites.

Take the Delta ORION power controller for instance – the mind behind everything from optimizing rectifiers and managing battery health, to connecting all site hardware to the Internet of Things (IoT).

ORION’s unique feature and the source of its true power is the embedded powerful logic processing engine that allows to optimize the whole power system and the way it manages energy. All of this is easily manageable and configurable both locally and remotely.

But in this project, Delta engineers thought even further outside the box. If ORION could unlock the latent power of site backup batteries to buy grid power in the smartest way possible, the potential would be huge: especially when combatting this particular nation’s complex three daily grid power tariffs.

The first step for our operator was investing in cyclic li-ion batteries across 171 test sites, rather than traditional lead acid. And leveraging time-shift functionality followed – discharging the new batteries at 35% at the highest cost tariff between 9 pm-midnight and recharging at the lowest tariff in the small hours.

But what about safety? Smart monitoring mitigates the risk of not being able to meet mandated power backup requirements – the batteries remain ever-ready to kick in and take over if there’s a power outage.

Switch. Save. Take control.

So what kind of savings can you expect from making the switch to li-ion batteries?

Tariffs vary from nation to nation, so results will fluctuate accordingly.

But nonetheless, it’s a clear success for our client: by saving 12%-15% per site, instead of paying for new batteries every 7-8 years, it gets them for free.

Connecting securely via the cloud to MultisiteMonitor (MSM) puts real-time monitoring and control and your fingertips. A server-based software tool, MSM gathers critical operations data from up to 3000 connected sites and stores it in a database to enable real time alarms, monitoring, and maintenance.

With a real-time status view and the ability to monitor multiple sites from anywhere from a remote PC, MSM empowers you to optimize energy management and battery status, check and modify configurations, distribute firmware updates, and maintain a detailed equipment inventory.

All said, this innovative application simplifies offloading a small portion of energy from the grid, or a larger amount in specific groups of sites.

So what could be the impact of these smart power savings at a national and regional level?

Two hour battery backup requirements with 10kW of load means operators have to install 20 kWh batteries ( ~400 Ah) per site. If we multiply this by 3000-5000 sites to reach national level, it equates to 60-100 MW energy stored possibly with one operator per country.

When you consider there are 723,450 telecoms towers across Europe, the potential savings are huge. And the benefits are environmental as well as financial – because optimizing energy use rebalances national grids, thus reducing the strain of energy production.

Flexible and future-proof

Switching to li-ion batteries harnesses smart power way to tackle a complex tariff system – by leveraging a mandatory resource that usually lies dormant. And for any telecoms operator that’s serious about reducing rising energy costs, it’s a real eye-opener.

And there’s more. Because as well as unlocking significant grid power savings, smart power also prepares you for the flexibility market: unlocking all that latent battery potential can be the first step away from grid reliance and towards a renewable future.

So, the next time you’re due to change your site backup batteries, remember to think smart.

If you’re interested in learning more about the potential cost savings of li-ion technology, we invite you to explore further. Feel free to reach out to us by using the contact form below. Our team is here to provide you with additional information and assist you in getting started on your journey to maximize cost efficiency with li-ion technology.

Despite progress in digital infrastructure across Eastern and Central Europe, there remained a critical need for reliable, purpose-built data centers. This challenge was met by one of our leading telecom data center clients, spearheaded by telecom and tech expert Üllar Jaaksoo. Their solution? The construction of the largest data center in the Baltics, designed to deliver unparalleled reliability and security. Central to this vision was the selection of the right UPS systems, and this is where Delta’s expertise played a pivotal role.

Building a Landmark Data Center

As part of the Three Seas Initiative (3SI) aimed at strengthening EU cohesion, the Tallinn data center is more than just a facility; it symbolizes the powerful intersection of public policy and private enterprise. Spanning 14,500 m² with a 31.5 MW power capacity, this cutting-edge data center is set to ensure reliable digital services across the region.

The Unique UPS Needs

Each private suite within the facility is equipped with its own dedicated UPS – a distinctive feature that sets this data center apart. This design enhances transparency in power consumption and minimizes risks associated with power disruptions. The challenge lay in finding a provider that could meet these specific needs while also supplying modular UPS units for the entire facility.

Delta’s Comprehensive Solution

After a thorough selection process, our telecom client chose Delta, largely due to our extensive UPS portfolio, which ranges from 1kVA to 500kVA. Delta’s UPS models stood out for their technological superiority and competitive total cost of ownership. A critical moment in this decision-making process was the client’s visit to Delta’s Experience Center in Soest, Germany.

Experience the Power

The Delta Experience Center in Soest is more than just a display of our capabilities—it’s a testament to Delta’s commitment to power innovation. Visitors here can witness the immense 3.6 megawatts of raw power, demonstrating the full potential of Delta’s UPS systems. This hands-on experience allowed our telecom client to see firsthand the efficiency, reliability, and durability of our solutions, ultimately solidifying their decision to partner with Delta.

Smooth Execution in Testing Times

Despite the challenges posed by the pandemic and the complexities of new construction, the project advanced smoothly, supported by Delta’s partner, DC Solutions Estonia. Any minor issues during installation were swiftly resolved by Delta’s support team based in Slovakia, ensuring that the Tallinn systems became fully operational as planned.

A Testimony to Collaboration

The Chief Development Officer of our telecom client, Kert Evert, praised the project’s success and emphasized the crucial role that Delta’s UPS solutions played. Likewise, Margus Sinisaar, CEO of DC Solutions Estonia, and myself, Pertti Lipponen, Sales Manager at Delta Solutions Finland, celebrated the long-standing collaboration that brought this project to fruition. With the Tallinn data center now fully operational, the region is well-positioned to harness the potential of digital advancements, all while benefiting from unmatched power reliability.

Tough at the top

The Delta team only fully understood the challenge after visiting Trollstigen.

Skirting roaring waterfalls and bottomless Fjords, this road passes mountains like The King (1614m), The Queen (1544m) and The Bishop (1,462m).

The lofty location and nature reserve status mean ´on-grid` isn’t an option – it’s prohibited by both expense and environmental regulations. And with a near sheer climb of 700m from viewing platform to peak, installing an off-grid base station would be a highly technical game of chess.

In terms of connectivity, only the viewing platform itself had mobile coverage. And accessibility posed problems too, because the road is closed (and site snowbound) each November to April.

So with no grid plug point and head-scratching access challenges, we needed to think way outside the box to pull off this ‘impossible’ project.

Building outside the box

Delta’s team of experts got straight to work, designing the unique infrastructure and formulating a plan for the tricky installation.

Installation engineers would only be able to work onsite during summer months, living onsite for several days at a time (this would be no 9-5 shift). Most of the components would need to be flown in by helicopter, with the remainder delivered by hand. And after the team left, the site would have to operate safely, efficiently and completely unmanned – with only limited opportunities each year for maintenance visits.

Back at the drawing board, the Delta team calculated all these complex criteria and developed an extraordinarily smart solution and viable execution plan.

Since off-grid power was the only option, we harnessed two of Trollstigen’s most abundant natural resources – wind and solar power. Then combined these elemental forces with lithium-ion batteries to power the site and hydrogen cells as a backup (should wind or sun fail).

Several partner companies collaborated. For instance, other stakeholders designed and delivered the wind turbines and PV panels and hydrogen fuel cells. Our mission was the cornerstone – producing an innovative power solution that actually made the station viable.

Digging a little deeper, the challenge was integrating these energy sources in a low-maintenance solution working year-round in extreme temperatures, without using excess energy to maintain heat. Therefore, the team decided to place the power systems and batteries in outdoor cabinets that could be heated separately, thus greatly reducing energy use and simplifying maintenance.

But how about the power system setup in the cabinet?

The unique configuration uses 8 of the latest, high-efficiency Eltek solar power modules (3.2 Kw each). And a rectiverter module which converts DC to AC (essential because the wind turbines have AC-powered magnetic brakes preventing them going out of control in extreme conditions).

An Eltek Power Monitor connects to the wind turbines and hydrogen fuel cells, to measure and control currents. And the solar inverters connected to the panels? The solution doesn’t require additional equipment when connecting to hydrogen. The turbines produce the correct voltage. Our primary job is to measure the energy produced by the wind and fuel cell sources.

The solar panels are also divided into strings, with one string on the cabin roof and 2-3 on the mast mounted vertically. They have a nano coating that ice or snow slides off and work surprisingly effectively, despite climatic extremes.

From late November to early February, Norway doesn’t get much sun. But from March until the end of September, solar output is quite good. And because Norway is colder, the PV panel efficiency is higher than in warmer regions.

Clever stuff indeed. But how would Telia monitor this remote site during harsh winter months? Not to mention the problem of getting the equipment (and installation engineers) up there to build it.

Remote control and monitoring

Way before the site was operational, our team had to ensure it could be controlled and monitored remotely – with pinpoint precision.

Enter the multi-talented Smartpack 2 Touch controller. For starters, this intelligent device automatically decides which power source has priority. Solar is first in the pecking order, so when the PV panels have gathered ample energy, the controller shuts down the fuel cell (if it’s running). Alternatively, when wind can produce more power, it instructs both sources to work together to optimise.

All units (including onsite heating and other components) are controlled by the Smartpack 2 Touch. There’s remote access to the site via Telia’s own network management system, and Delta developed software to communicate directly with the fuel cell controller. Maintaining the optimum temperature is all-important in this setup. There’s also a small, temperature-regulated, panel oven in the cabin. It’s crucial to maintain the perfect temperature inside, because the by-product of hydrogen is water and if the temperature drops below freezing, the water could turn to ice and damage the fuel cell internals.

And thanks to an ongoing service agreement, Delta provides ongoing support. Because getting your friend up the mountain is one thing but leaving them stranded another. Telia are their own first line of support. But (if necessary) Delta personnel will visit the site annually for system testing to ensure optimal operation, as well as working remotely analysing log files.

Plus, should Telia ever want to expand or alter the site, the Delta team are ready to help. For example, Trollstigen is currently a groundbreaking 5G installation, but it’s also scalable for 6G and other emerging tech evolutions.

Sky’s the limit: installation and maintenance

With all components packed and the installation team ready, it was time to fly in the lion’s share of the kit by helicopter. And the chopper also dropped off a super-lightweight camper unit for Trollstigen’s engineers/mountaineers.

Between summer 2018 and summer 2019, the intrepid team worked in shifts for the 2-3 months when weather permitted. A tough task. But immense job satisfaction and gorgeous Northern Lights views compensated for the challenges.

Telia was delighted once the site was operational. And Delta is immensely proud that the team had conquered mountains other experts avoided.

The technical solution is seriously impressive. But the true foundation for this project is just as rare and powerful: building complete trust within and between organisations.

Telia trust that we will come up with good solutions. But it’s not only about selling the product. It’s also about being there for the customer when things aren’t working as they should.

And the mutual internal trust between Delta colleagues is also vital. Having the support of the organization made this project possible. Our organization is open to innovative ideas and also lets you know what’s not feasible. This trust and support gave us the confidence to be a reliable advisor for the client.

So there it is. A green, off-grid Telecoms site supporting 5G connectivity in a jaw-dropping site.

Where visitors now snap and send stunning selfies instantly from Trollstigen to the world.

Built by trust and technical excellence – from the ground up.

Talk to us today about your impossible project.

Understanding Renewable Power Consumption: A Broader Perspective

While Trollstigen relies heavily on natural resources like wind and solar, it’s worth noting in general how other renewable power systems compare in terms of their reliance on diesel, a commonly used backup energy source.

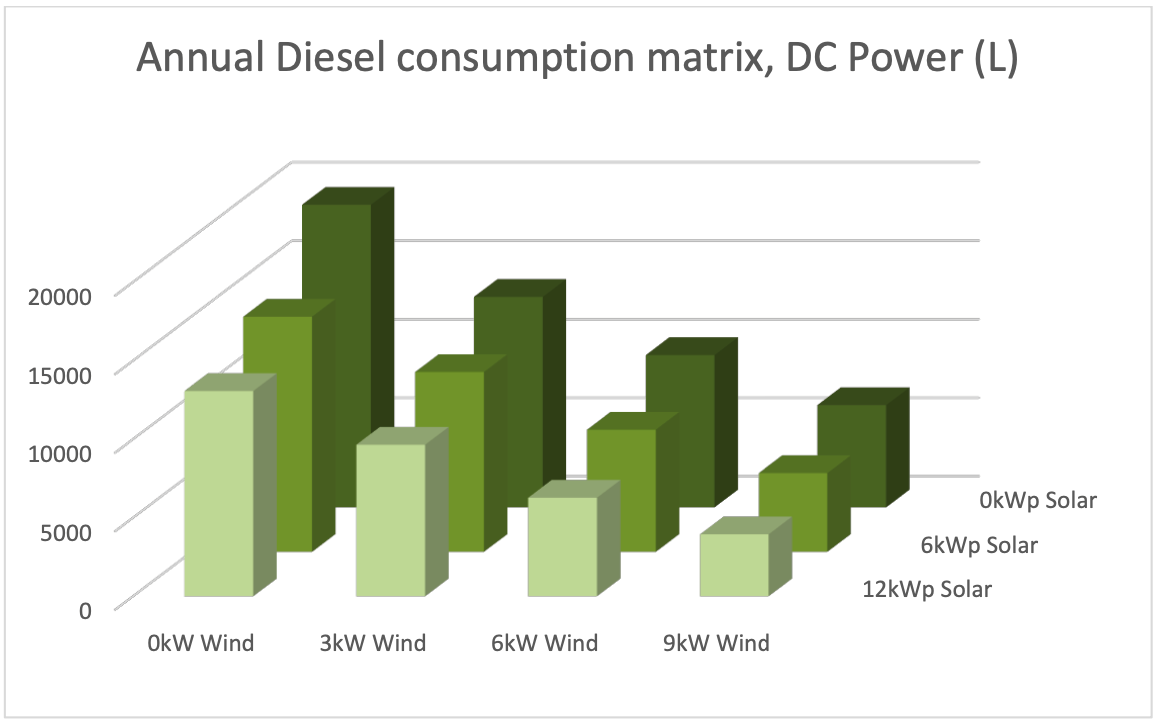

The matrix below provides an understanding of how introducing varying mixes of wind and/or solar to a power system can impact diesel consumption. The goal? Minimize the refueling visits, especially in hard-to-access locations, while maintaining energy efficiency.

Renewable energy not only helps in cutting down greenhouse gases but can also significantly reduce lifetime costs for such projects. Integrating renewables in power systems demands a careful evaluation, ensuring the balance between cost-effectiveness and reliability.

Substantial Cost Savings

This swift deployment didn’t just fast-track operations; it also generated substantial cost savings. Our innovative approach slashed costs by up to 20% compared to conventional construction methods, handing our client a significant financial advantage.

Broadening Geographical Reach with Modular Design

Our modular design offers more than just speed and cost benefits. Meticulous engineering has made transporting these data center modules across Europe both cost-effective and straightforward, empowering our client to harness the power of advanced data centers, regardless of their geographical reach.

Enhanced Operational Efficiency

We’ve mastered the assembly process, demonstrating unparalleled engineering prowess as we accurately aligned and sealed the individual modules. The integration of cabling and piping epitomizes our commitment to operational efficiency, further increasing the data center’s overall effectiveness.

Cutting-Edge Technology for Optimized Performance

To heighten performance, we’ve incorporated the latest technology, including cutting-edge cooling systems, intelligent airflow management, as well as Delta´s highly efficient UPS and Eltek´s Rectiverter. This results in optimal temperature control and reduced energy use, cutting operational costs by up to 30% and promoting sustainable operations.

Uninterrupted Power Supply and Business Continuity

The attention paid to power distribution and management is exceptional, employing advanced power modules and smart grid integration. This has bolstered reliability and scalability, guaranteeing an uninterrupted power supply and business continuity. Our robust infrastructure has achieved an impressive 99.9999% availability rate.

Advanced Cybersecurity Measures

In the face of digital transformation, security is of utmost importance. To ensure absolute safety, we’ve woven advanced cybersecurity measures into the fabric of the data center’s design. This multi-layered defense strategy guarantees the integrity and confidentiality of critical data.

Future-Proofing Data Centers for the Digital Era

Our modular data center is future-proof, ready to embrace upcoming technologies such as 5G and IoT. Our flexible design ensures that our client is well-equipped for the digital era. Delta provides an end-to-end service, taking responsibility from contract to delivery. Our team of dedicated engineers adheres to the highest quality standards and utilizes groundbreaking technologies to turn ideas into reality.

Choosing Delta as your engineering partner empowers your business to navigate technological advancements with confidence. Our commitment to precision engineering and embracing technological innovation empowers clients to shape a future that is defined by cutting-edge innovation and unparalleled excellence.

Tackling Growth Challenges with Tech

TASK was facing problems. More demand on their supercomputer and rising data traffic meant they had to grow. But their old UPS power system was causing issues. They were siloed, the power output was limited, and they had phase problems, not ideal for their sensitive computer hardware. So, in order to scale the right way, they chose to be smart about it and made the jump from AC to DC.

Easy Switch with Delta’s Know-How

In a meeting of minds, TASK representatives – and later, Delta engineers – joined forces, sharing a mutual vision of intelligent and sustainable progress. 400VDC was a new concept at the time. Everyone was talking about it, but Delta had already implemented the groundbreaking 400VDC in the telecom market, rendering them the perfect partner for TASK’s ambitious transition. With Delta’s help, TASK saw a 20% boost in their power output.

More Flexibility and Efficiency with 400VDC

Adopting 400VDC enabled TASK to expand their data center optimally. The technology allows a higher power density, moving more power through each cable and freeing up to 30% more space. This new efficiency provided TASK with the flexibility to design their server floor to meet specific needs, including the capability to transfer power over longer distances, reducing the amount of required copper wire by a striking 80% compared to AC systems.

Making Room for Growth with 400VDC

Utilising the capability of 400VDC to transport power over extended distances, TASK effectively relocated their power systems and backup batteries further away from the main server floor. This shift created additional room for critical equipment, enabling a liberated floor space that fostered TASK’s potential for unrestrained growth and innovation.

“With 400VDC, we have the stability and flexibility we need to keep growing, allowing our supercomputer to continue to accelerate research and innovation.”

Task representative

Sustainability and Environmental Responsibility

Beyond scalability, TASK Data Center placed paramount importance on sustainability and reducing their carbon footprint. By switching from AC to DC, Delta makes it easy to add solar panels and other renewables into your energy mix so that you can minimise your carbon emissions as you grow.

In the Digital Age, Security Is Key

To ensure maximum protection, advanced cybersecurity measures have been seamlessly integrated into the design of TASK’s data center. This multi-tiered defense approach ensures the safety and confidentiality of all critical data.

The Future is DC

With an illustrious track record spanning decades in telecom data centers across Europe, Delta has continually driven innovation and fostered intelligent decision-making. The future undeniably belongs to DC, and the partnership between TASK and Delta serves as a testament to the possibilities of sustainable growth. Together, we will make the right decisions for your data center, so that you can be smart about it and grow the right way.